Everything About Flame Scanner

Flame monitoring system is used to detect formation of flame inside combustion chamber and to prevent fuel injection inside it in case no flame is formed. If flame dies, safety system of flame scanner acts within one second to close fuel valve. This way, fuel accumulation inside combustion chamber and probable explosion would be prevented.

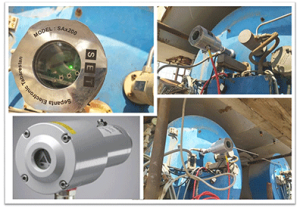

In continuation, components of flame scanner (model AGD01) manufactured by Sepanta Electronic Tabarestan will be explained. The mode is the most applied flame detection system produced by Sepanta which has been considered as the basis for other flame monitoring systems.

Components of flame detection systems:

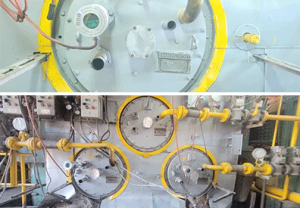

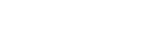

AGD01 Flame detector is consisted of two main parts:

- Flame sensor

- Flame analysis card

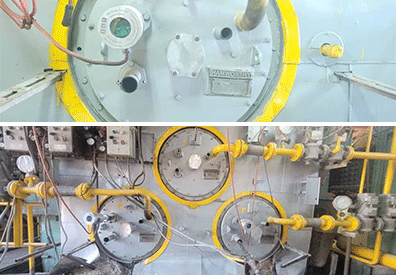

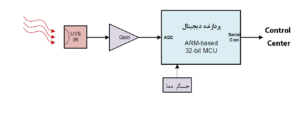

As observable in the figure, flame sensor receives light waves radiated from flame through one hole; and, it turns it to electrical signal by optical sensor. Then signal received from optical sensor will be studied in digital processor and flame quality characteristics would be extracted. Digital processor sends quality characteristics of the flame to central control room or central flame safety control system.

The system can operate under difficult environmental conditions such as 71ᵒC temperature.

Advantages of AGD01 Flame Scanner

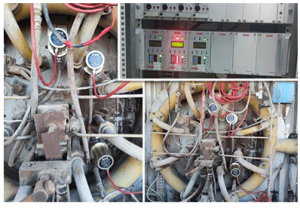

AGD01 flame scanner consists of one 32 bits digital processor from ARM family. In addition to performance of main task in flame detection system, processor provides some new capabilities as well:

Digital scanner is capable of detecting percentage of optical spectrum i.e. UV and IR percentages of received spectrum. This way, quality of the flame inside combustion chamber can be measured and compared to an ideal flame.

Digital scanner has detection capability of flame intensity inside combustion chamber.

Digital scanner has special software that being connected to amplifier card; it provides capability of detecting flame situation and review of it (figure 2).

Temperature inside scanner can be recorded for a long time interval that makes possible study of such temperature. Therefore, crack of side glass and hot air leakage can be easily detected through review of scanner temperature.

Data will be transferred digitally in physical RS458 platform and through Modus protocol which is much safe against environmental noise; and, destructive effects of troublesome signals in it are very low.

*flame monitoring system is a critical safety technology used in industrial applications to detect and analyze flame presence and behavior in real time.*

| MESC CODE | CAN BE REPLACED INSTEAD OF | PRODUCTS |

|---|---|---|

| First column | Second column | Thd column |

| First column | Second column | Third column |